Programmable safety-relay in the pharmaceutical Industry

The need

A crushing machine in the pharmaceutical industry is responsible for the separation, crushing, and processing of manufactured pharmaceutical products. The crusher is used to adjust the size of solid materials used in the drug manufacturing process.

Overall, this machine is an important part of the manufacturing process and ensures that pharmaceutical products comply with safety regulations to protect patients and end-users of pharmaceutical products.

The customer contacted us due to 2 faulty safety relays that were detected in the safety circuit of the particular machine.

The safety relay undertakes several tasks that include observing the safety sensor, identifying any issues, and implementing safety protocols to guarantee the secure functionality of machinery and the safety of the operators.

The problem

The existing materials were not readily available for replacement from the previous supplier. As the customer was faced with a serious operator safety issue, we were called upon to provide a reliable solution within a short timeframe.

Implementation

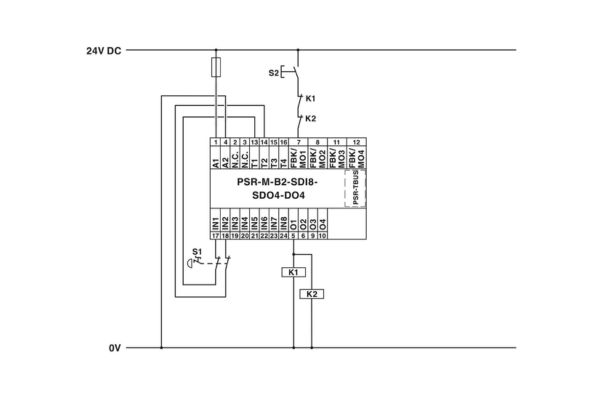

After studying the existing circuit our technicians suggested proceeding with a programmable safety relay solution from Phoenix Contact.

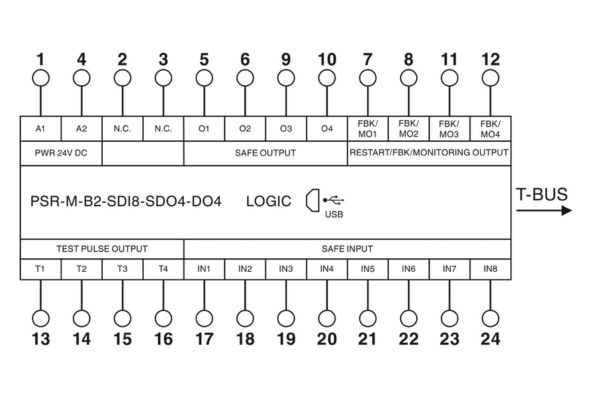

As a result, the customer replaced 2 (two) existing materials with 1 (one) which gave them a total of 8 input channels (instead of 2) and 4 outputs.

An important advantage of the Phoenix Contact relay is that it enables the replacement of a wide range of other safety relays, allowing the implementation of much more complex safety circuits as it is not limited by the specifications of other corresponding materials on the market.

This implies that the technician can use this relay for multiple security applications, without needing to purchase separate devices for each application. Additionally, in terms of preventative maintenance, the material can be kept in stock and configured in advance, enabling quick replacement in case of emergencies with minimal downtime.

Another important feature is that the programming of all relay functions is done internally, through software provided by the supplier.

The KSA technician downloaded the software to his computer and proceeded to remotely program the hardware according to the application requirements. All settings were then transferred very easily via mini-USB programming cable to the machine.

The software is available for free from Phoenix Contact and KSA can provide training on its use so that the customer is familiar should a similar need arise in the future.

Phoenix Contact Safety relay PSR-M-B2-SDI8-SDO4-DO4-SC is an expandable material that ensures minimum wiring, giving the user the flexibility to adapt it to the needs of their application, saving long-term costs and simplifying the installation process.

Benefits

- Prompt and efficient assistance from KSA Industrial Automation

- Programmable relay - covers a wide range of applications

- Free programming software from the supplier and the possibility of training in its use by KSA technicians

- Trustworthy solution with immediate availability

- Short downtime (as part of preventive maintenance)

- Expendable: offers possibilities for future upgrades

- Ensures minimal cabling