Enhancing Quality Control in Pharmaceutical Packaging

In the pharmaceutical industry, quality control failures in blister packs are a significant concern. Errors in the number, size, or type of pills can lead to consumer complaints or order returns from customers. To address this, industrial cameras are used in quality control applications to verify that blister packs are correctly filled. These systems check the position and condition of the pills and signal when faulty packaging should be rejected.

The need

Our client, a pharmaceutical corporation specializing in the manufacturing and global distribution of medical products, sought our assistance to enhance the quality control component of their pill blister machine.

The client’s existing machine came with a quality control system that included a camera and associated software. However, this system did not provide reliable results, causing the rejection of correct products or, conversely, failing to reject faulty ones. Additionally, the client expressed the need to increase the machine’s quality control levels.

Initially, the machine’s functionality was limited to checking the presence of pills of a specific color within the blister, along with verifying their size.

As the product range grew, the need arose for additional checks, particularly for the presence of multiple pill colors in a single blister.

The solution

Based on the client’s budget and requirements, KALAMARAKIS AUTOMATION proposed a solution that included system study, programming, and training in the use of the following components:

- OMRON: FHV7H-C032-C SMART CAMERA

- OMRON: PLC CP2E (discharge tuning)

- Infrared Ring Lighting

Outcome

Once the programming was completed by our specialized team, the client was able to easily install the solution on their machine.

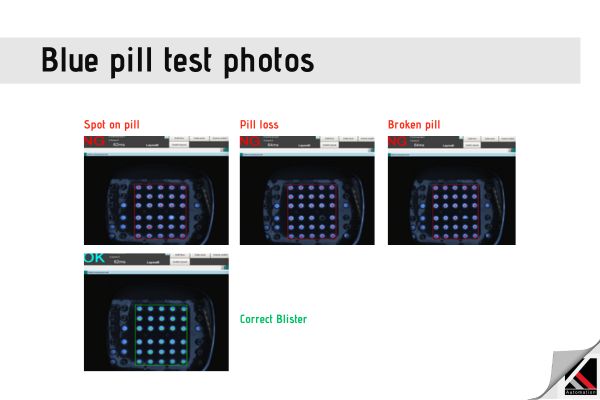

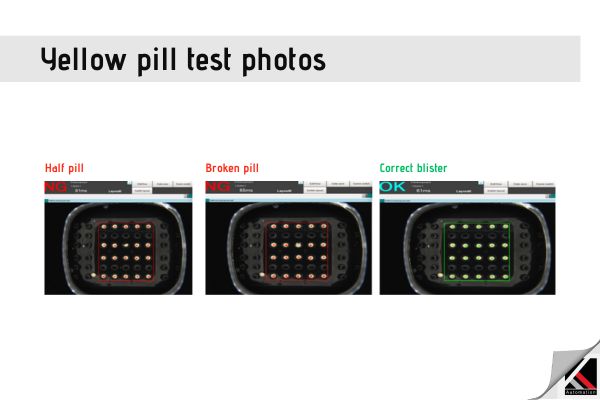

The outcome of the upgrade exceeded the client’s expectations, as the machine now featured five levels of quality control:

- Pill marking

- Missing pills

- Broken pills or missing parts (size verification)

- Pill color recognition

- Cracked pills

In addition to fulfilling the original request, the solution also provided two additional levels of control, greatly enhancing the overall quality control capabilities of the client’s machine.

Additional Benefits

The solution was easy to install, operate, and maintain.

Furthermore, when packaging formats change, the system does not require re-parameterization, allowing the machine to handle different pill sizes and quantities per blister with ease.

Finally, the client benefits from the expertise of KALAMARAKIS AUTOMATION, ensuring prompt technical support in case of any issues, and preventing significant production downtime.

"You can rely on our experience and diverse product selection to upgrade your equipment.

Contact us to explore the most suitable options tailored to your specific needs!"