Selecting air-conditioning for electrical panels

In the summertime, the combination of intense heat and constant machine usage can lead to a significant increase in temperature inside the electrical panels of the factory. Consequently, this overheating affects the vulnerable components that are sensitive to high temperatures, including power supplies, inverters, and programmable logic controllers (PLCs). As a consequence, these overheating issues have the potential to cause malfunctions or even halt production.

“Proper and efficient air conditioner cooling can significantly extend the life of installed equipment, save energy and costs as well as reduce production stoppages.”

The combination of the high environmental temperature and the continuous operation of the machines can result in a significant increase in temperature within the panels. This can result in overheating of heat-sensitive components such as transformers, inverters, and PLCs. The consequences of this overheating include:

- Damage to electrical and electronic components

- Production stoppages due to panel damage

- Increased costs for repairing components

- Concentration of a high percentage of relative humidity inside the panels

- Reduced lifespan of components, as the lifespan of electronic parts is halved when the ambient temperature exceeds 35 degrees Celsius

To prevent these issues, it is necessary to install special air conditioning units that can cool the electrical panels and protect their contents from overheating.

Two sources cause the temperature inside the panels to rise above the allowable limits of the component manufacturers.

Internal sources

The panel components themselves that experience overheating damage are usually the main sources of heat. The electronic parts and components contained in the panel generate thermal energy derived from the unused electrical energy they consume.

Such components are:

• Transformers

• Inverters

• Servo-Drives

• Power-supplies

• Batteries

• Current switches

• Power relays

External sources

Other sources of heat that increase the internal temperature of the panel above the desired limits are due to the external environment. For example:

• Industrial Ovens

• Foundry Equipment

• Thermal burden from radiation

• Blast furnaces

The problem of overheating is ideally dealt with by installing new-generation air conditioning units.

New industrial air conditioning systems offer high efficiency, significant energy savings, minimal maintenance costs and environmental friendliness.

Caution!

• Fan ventilation leads to damage from dust and particles suspended inside the panels.

• Operating panels with doors open for natural ventilation, increases the risk of operator accidents.

Choosing the right air conditioner for your panels and fields has a big impact on overall plant efficiency.

The right choice of cooling system can extend the life of installed equipment, save energy and costs of operation and maintenance as well as reduce production stoppages.

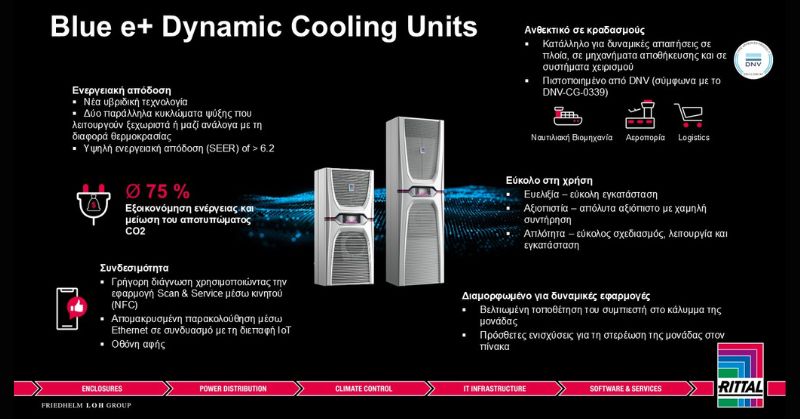

Characteristics of RITTAL Blue E+S cooling units

• Average energy savings of 75%, thanks to Heat pipe technology

• Reduced CO2 footprint

• Use of R-513A refrigerant, which makes them more environmentally friendly

• Unique multi-voltage capability for wide use (single-phase and three-phase connection, 50/60Hz)

• Touch screen, so that settings can be made immediately and very easily

• Efficiency rating reaching EER 3.4 and SEER 8.1

• Operating temperature from -20°C to +60°C

Annual maintenance by qualified Rittal technicians, with a written warranty on parts and labor

Complete the contact form and we will contact you to assess your own air conditioning needs:

• Calculation of heat losses inside the panel

• Determination of the cooling performance (Watts) required for the correct air conditioning of the panel

• Proposal for alternative air conditioning units